GI SYSTEM CONSTRUCTION PROCESS MANAGEMENT SYSTEM

It realizes reliable construction and high quality control.

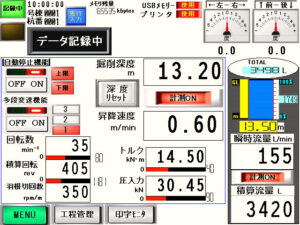

Construction process management system・Construction process support function (latest touch panel, USB memory data storage method).

Construction process management system

Equipped with a 7.5 inch(115.8 x 153.7) clear large screen with touch panel, the device can record real time operation data. The results can be printed or be stored in USB.

In addition, there are many “useful” functions and information necessary for construction such as “Constant speed control device” that can set 3 speeds, “Feed operation automatic stop device” that automatically stops the drilling operation when the target depth is reached and “Print confirmation function” that allows to check the latest printing status of the printer on the monitor.

|

■Construction process support function

In order to secure the quality of the column for ground improvement work, it is required to be constructed as designed. However, it is very difficult to calculate the flow rate of cement milk and to consider how to construct at the site.

It simplifies operator’s work and supports the construction with stable quality.

It is the best support system for the improvement of construction quality that can be achieved only by YBM who knows the ground from the geological survey to the ground improvement.

|

Construction condition calculation function

|

column connection management setting screen

|

Construction process support function

■Construction process management system

It supports following parameters.

- Cement milk flow rate calculation

(total flow rate per column) - Target flow rate reaching notification

- Target depth reaching notification

- Flow rate and feed speed calculation

- Mud balance calculation

- Cement consumption calculation

- Flow rate per 1 m

- Number of mixing blade rotation calculation

- Combination table of cement and water

■Steel pipe piling construction support.

It supports following parameters.

- Target depth

- Pile head level calculation

- Automatic data record for torque and feed pressure

- Pile connection control

■Total flow rate printing function

- Depth and total flow rate

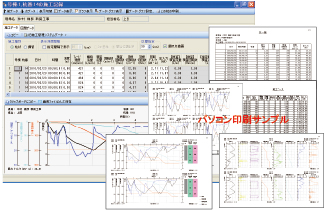

■Data processing software 「YBM construction process management system」

“YBM construction process management system” can read and save the data recorded in the USB memory device at the site. These 4 types of data such as “pile list”, “construction data”, “construction graph” and “section data (flow rate per 1m, number of blade cutting per 1m)” saved in the construction site can be printed out using this software. And it can be used as a construction report.

General USB memory card used

The construction data can be saved in the hard disk in the form of general-purpose software such as Excel, and can be arranged by the customer with the dedicated software.

Please prepare a data processing PC (Windows) with USB memory.

Data processing software (2007) is compatible with Windows XP SP3 / Vista / 7.

Data processing software (2013) is compatible with Windows XP SP3 / Vista / 7/8.

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.