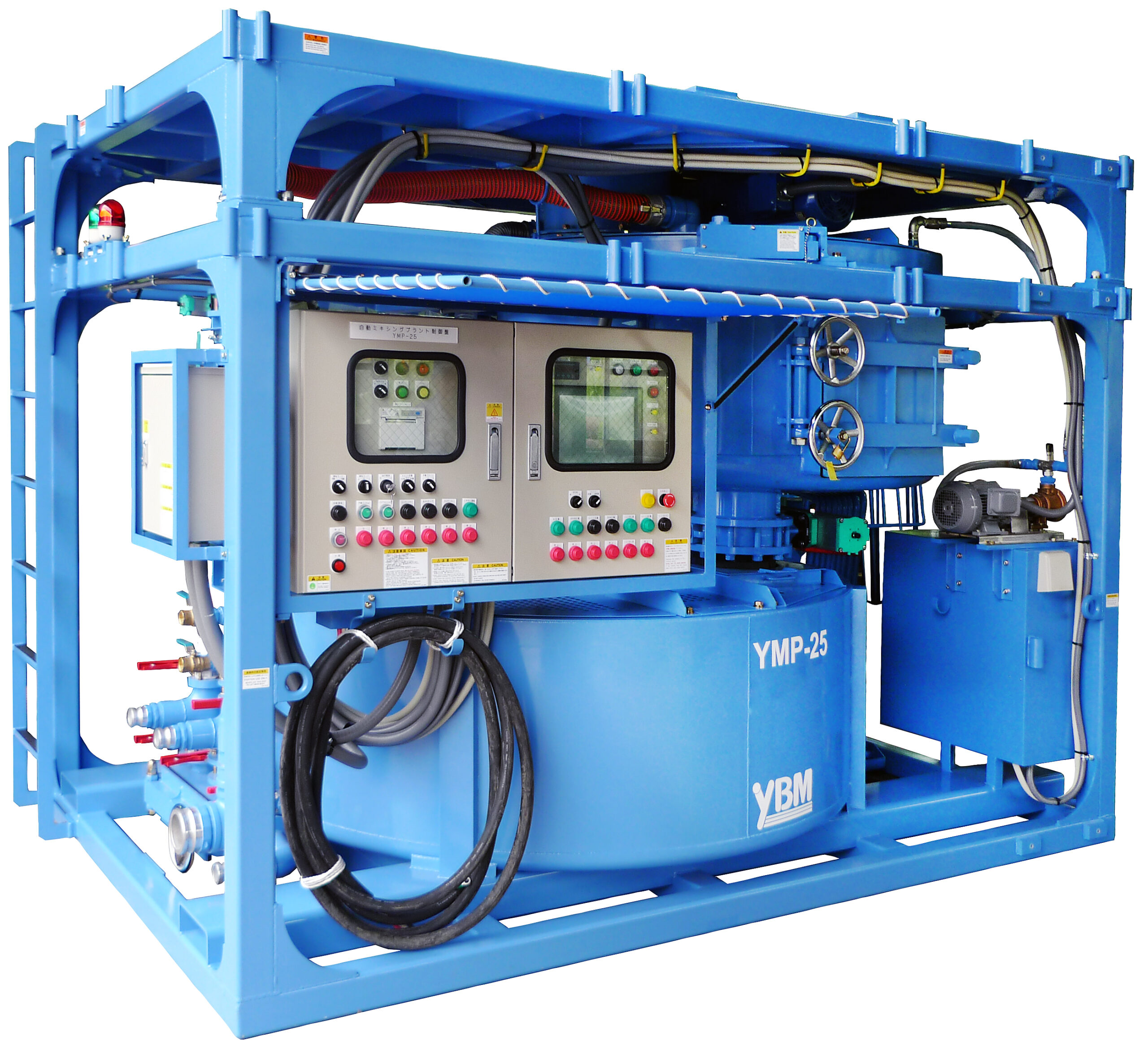

Full AUTOMATIC MIXING PLANT

YMP-25Ⅱ

- Just set the cement and water volume on the control panel, automatically measure and adjust inlet volume of them.

- Modified bigger mixing tank increases its capacity for 1320L cement milk(ratio water /cement 1,000kg / 1,000kg).

- As automatic measurement of the cement volume in Agitator, it can be relieved from shortage of the cement slurry and constructed continuously.

- The batch counter allows continuous construction all day long.

- Amount of water and cement are recorded to calculate daily total amount.

- Simple and easy cleaning structure with larger maintenance door.

Specifications

| ◆Productivity | ||||

|---|---|---|---|---|

| Productivity *1, *2 |

25 m3/h (415 L/min) (1m3×25 batch/h) |

24 m3/h (400 L/min) (1m3×24 batch/h) |

21 m3/h (350 L/min) (1m3×21 batch/h) |

20 m3/h (330 L/min) (1m3×20 batch/h) |

| Mixing pump *3 | 5.5 kW 100A (1.6 m3/min) |

5.5 kW 100A (1.4 m3/min) |

5.5 kW 80A (0.9 m3/min) |

3.7 kW 80A (0.8 m3/min) |

| ◆Mixer | ||||

| Mixing capacity | 1,320 L | |||

| Tank volume | 1,600 L | |||

| Motor output | 7.5 kW 1/11 Gear motor Rotation speed 138 min-1/167 min-1(50Hz/60Hz) | |||

| Measurement | Load cell type | |||

| Cement milk outlet | ⌀300 mm×1 | |||

| ◆Agitator | ||||

| Capacity | 2,100 L | |||

| Tank volume | 2,400 L | |||

| Motor output | 1.5 kW 1/100 Gear motor Rotation speed 15 min-1/17min-1(50Hz/60Hz) | |||

| ◆Dimension / Weight | ||||

| Dimension | 3,380× 2,100 × 2,450 mm (L×W×H) | |||

| Weight | 3,800 kg (excluded option items) | |||

| ◆Options | ||||

| High pressure water cleaner | 3.7 kW | |||

| Cement Hopper | For 1 ton bag | |||

| Additive Pump | 1.5 kW 160/200 L/min(50Hz/60Hz) | |||

| Water hose | 100A or 80A | |||

| Cement Silo | When the cement silo to be mounted, its structure is changed to the reinforced type. | |||

1:When using 2 sets of Cement Silo which have a capacity to supply cement powder 50ton/h.

2:Ability depends on the w/c ratio or type/quality of Cement.

3:Options

The specifications are subject to change without prior notice.